-

-

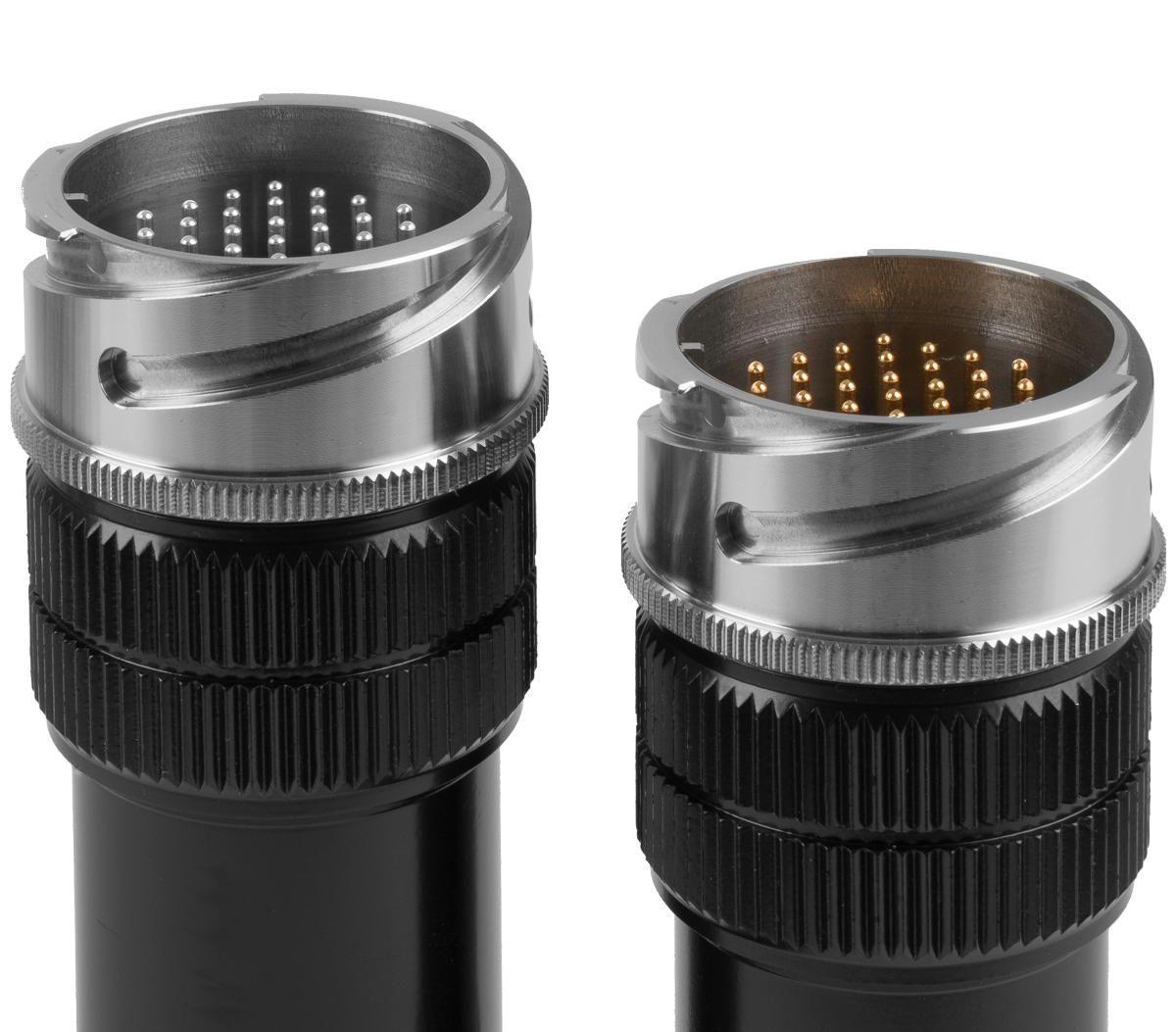

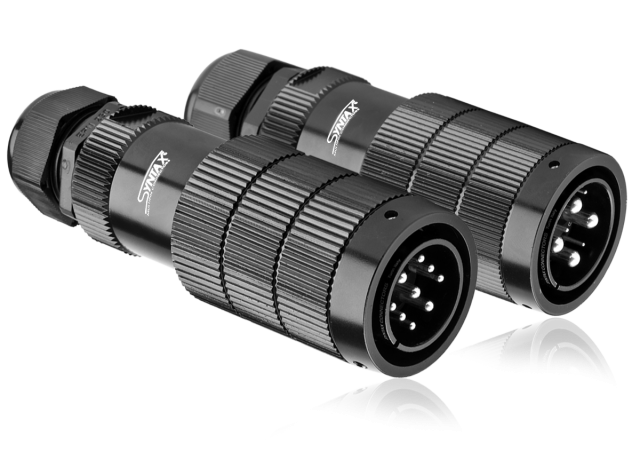

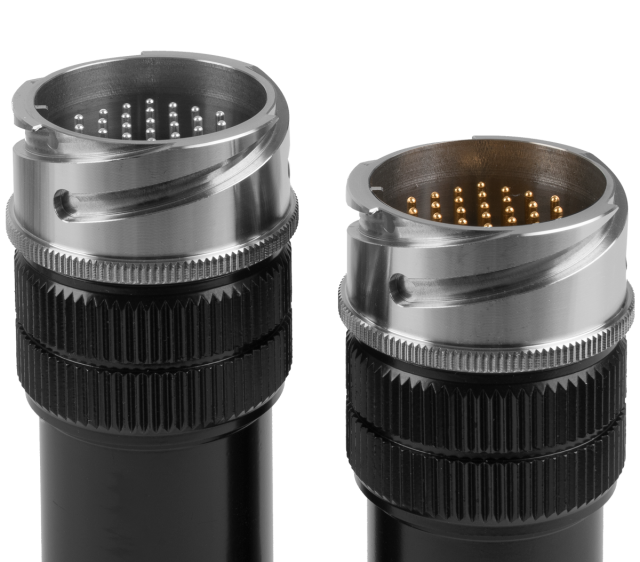

The multipin connector

you were looking forThe multipin connector

you were looking forMany different series, shell sizes and

arrangements for up to 150 contacts.Many different series, shell sizes and

arrangements for up to 150 contacts.

Our Syntax circular bayonet mount multipin connectors are built in compliance with SAE AS50151, formerly known as MIL-C-5015, and VG 95234 military standards, so they are designed and built to be tough and reliable, but they are also extremely versatile, suitable to a vast range of both indoor or outdoor applications and to carry signal and/or power, depending on the type of connection the job requires.

-

Explore our range of products and find the connector you need.

Explore our range of products and find the connector you need.

-

-

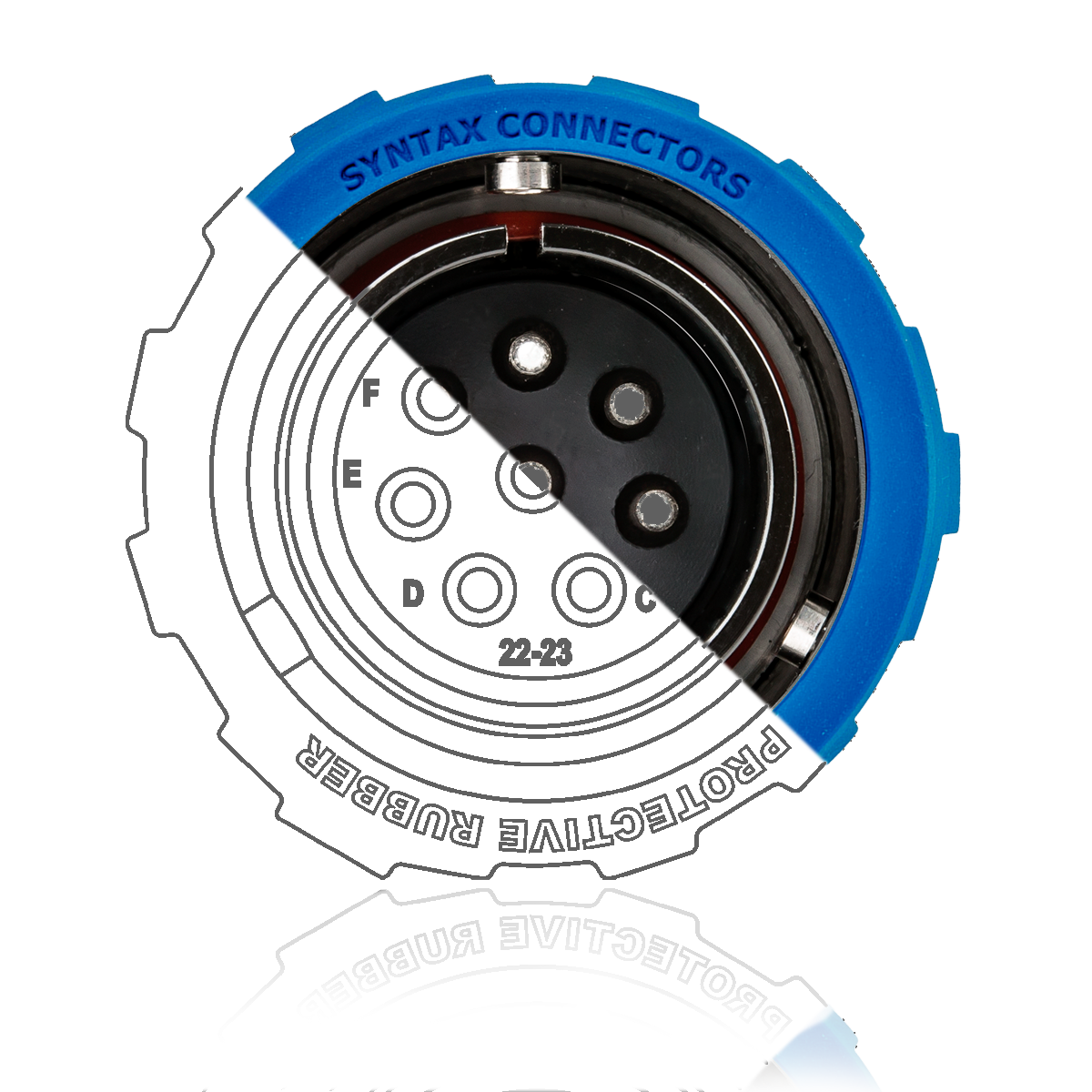

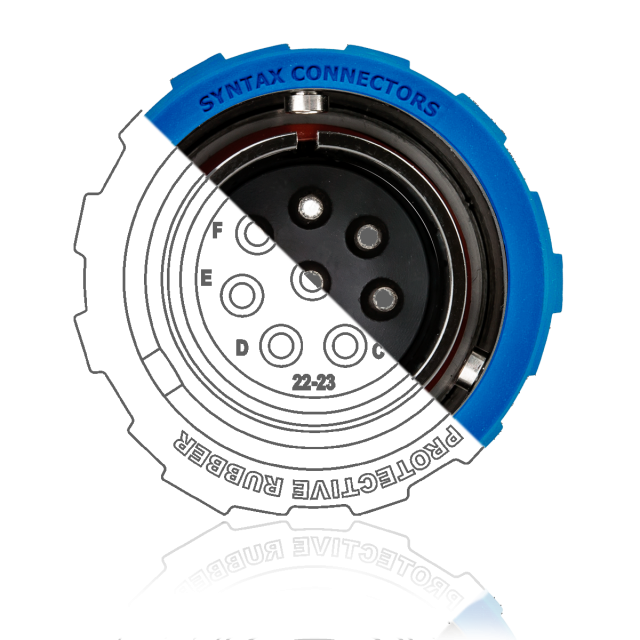

Always identify

your connectorsAlways identify

your connectorsRubber coated locking rings

Rubber coated locking rings

Ideal for your everyday work, extremely resistant to shocks and compression, smoothest insertion, best grip with or without gloves. For quick identification of your cables through color coding, multiple color options are available in stock. Customized color options are also available on request.

-

Waterproof

your connectorsWaterproof

your connectorsIP67 protective caps

IP67 protective caps

Environmental caps are available on request and provide complete IP67 protection on unmated connectors. The use of protective caps results in extended life span of the connectors as the mating threads are protected against damage from impacts and improved safety as contacts are protected against dust and water even when the connectors are not mated.

-

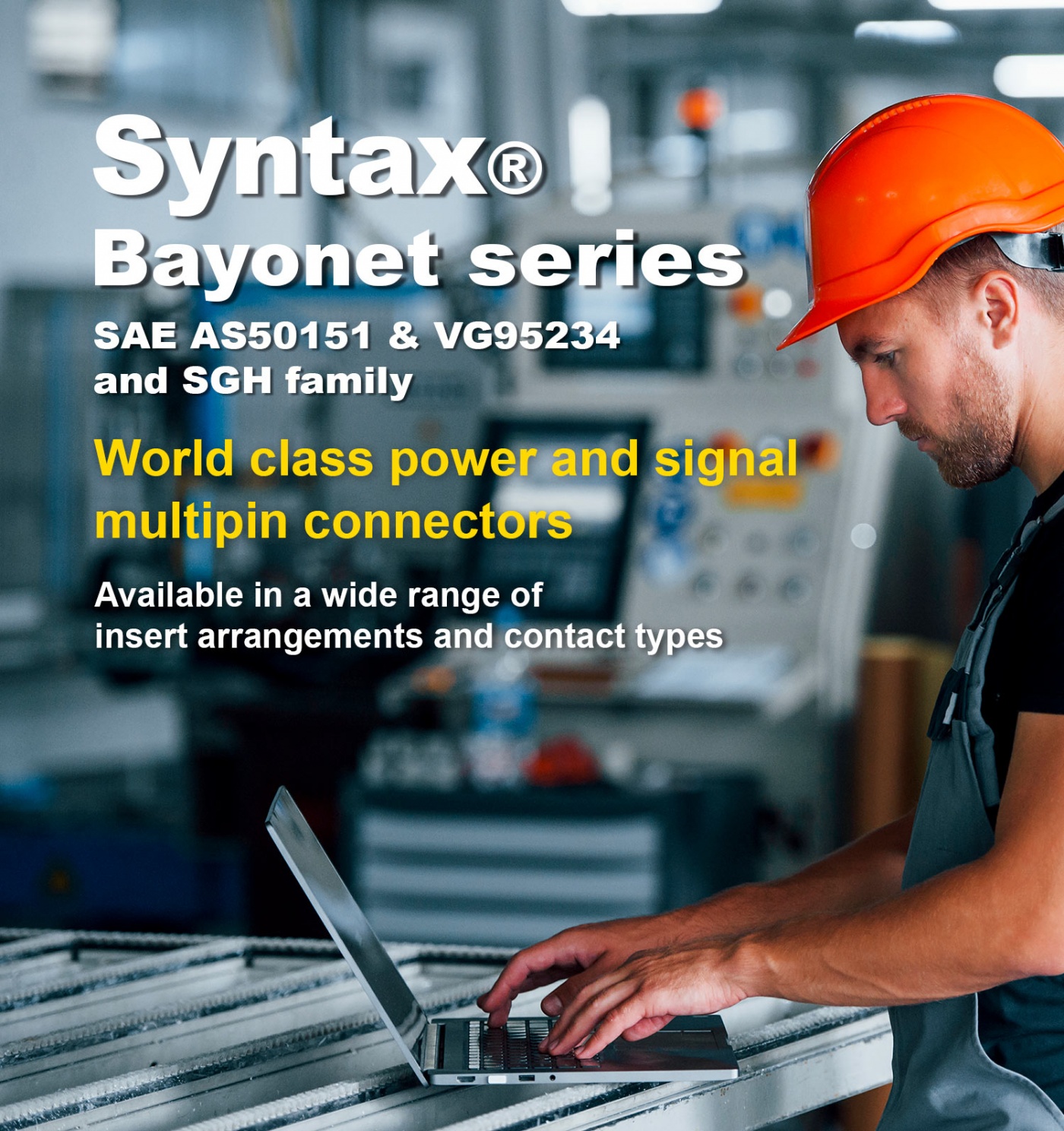

SGH

Syntax® Gigamod HybridSGH

Syntax® Gigamod HybridHybrid & modular circular connectors for countless combinations

of Ethernet/HDMI/USB3 and PowerHybrid & modular circular connectors for countless combinations

of Ethernet/HDMI/USB3 and PowerA central insert carrying power or digital signals. A circular outer shell with up to 16 contact modules for multiple Ethernet, HDMI, USB3 signals. Mechanically interlocked elements that open up a world of possibilities for your jobs in so many fields. Combine them and create your solution.